What is preventing your team from delivering a world-class turnaround?

Close the gap between possibility and performance.

Benchmark studies offer useful high-level insights, but have several critical shortcomings.

- Two refineries may look similar on paper but operate under vastly different realities.

Turnarounds are deeply situational. Without understanding the why, comparisons are often misleading. - Benchmarks may identify gaps, but rarely show how to close them.

- A refinery may rank in the top quartile and still have massive inefficiencies or safety risks.

- Benchmark studies are a lagging indicator that doesn’t account for evolving strategies and changing market conditions.

Execute your next turnaround with greater confidence.

A TAR360 Assessment is a strategic, context-rich approach that translates directly into action and results.

- Replicate successes and draw on site strengths.

- Tackle persistent issues to meet safety, schedule and cost targets.

- Get to root cause and eliminate recurring problems.

- Identify and address future constraints.

How do you close the gap between what you know is possible and what you are actually achieving?

TAR360 helps you cut through the noise and complexity to identify and incorporate the right strategies for your site.

We have worked with senior leaders and frontline teams to execute projects all over North America

What is TAR360?

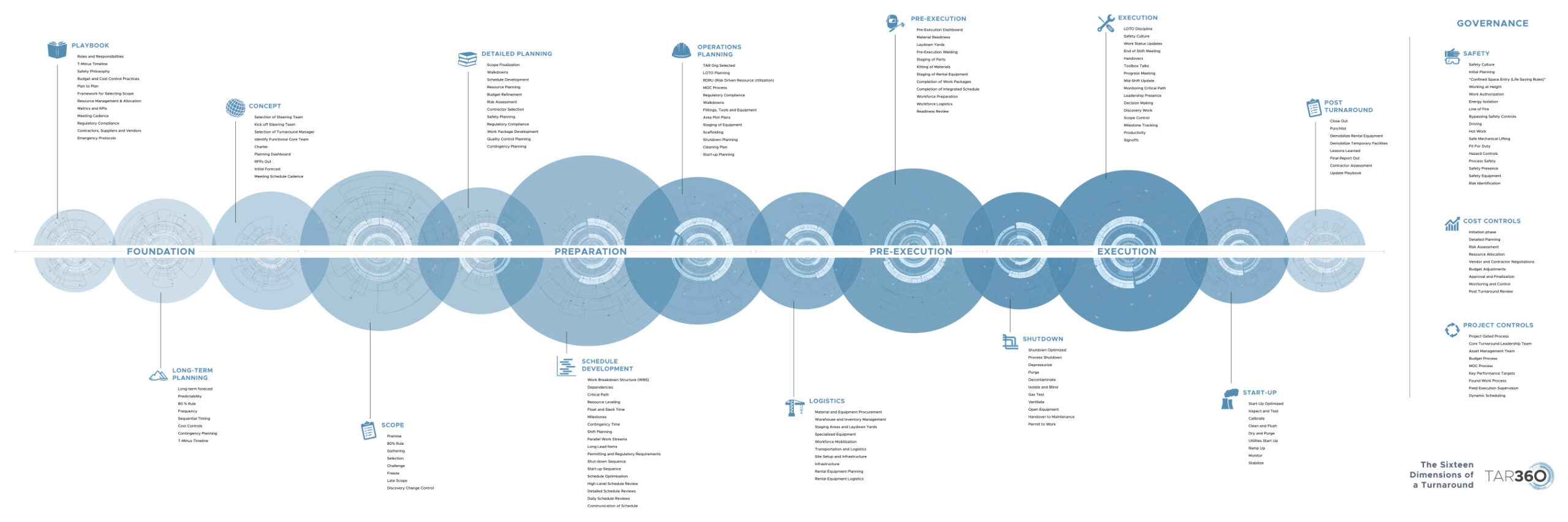

TAR360 utilizes a 16 dimension framework to assess and identify the most important capabilities and gaps in an organization’s ability to successfully pull off a turnaround. This framework allows us to cut through the noise and complexity to identify the highest leverage opportunities to control and improve performance at your site.

Schedule A Meeting with a TAR360 Representative

Pick a time and day that works well for you and we will meet you via zoom to discuss your project.

Reach out to explore how a TAR360 Assessment would work at your site.

A member of our team will reach out to you within the next 24 hours.

Case Studies

Finding the Root Cause of Scope Creep

Turnarounds at a SAGD operation in Canada were consistently 2nd quartile. They wanted an external set of eyes to review their processes and identify what

The Consequences of Falling Behind

Another finding of the assessment at the SAGD operation highlighted their struggle to find contractors who could deliver on time and to standard. This was

Adopting Best Practices in Industry

A US refinery that had consistently achieved 1st quartile turnaround results fell to 3rd quartile, incurring nearly $10M in lost profit opportunity and additional labor